Position:Home> Product

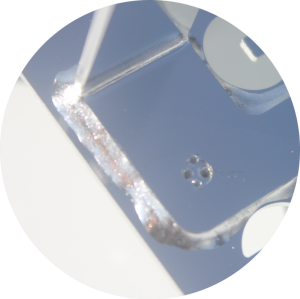

Laminated Copper Busbar Welding Accessories

| Material | T2 copper foil |

| Features | 1.Strong welding, no gap with excellent appearance 2.Perform excellent thermal conductivity, ductility and corrosion resistance, and has good weldability. 3.Good reliability and space saving |

| Specification | OEM or ODM is availbable |

| Certificate | TS16949 & ISO9001 |

| Application | Widely used in electronic parts of electrical components, electrical products |

Product Information

1.The Cu content of Laminated Copper Busbar Welding Accessories is greater than 99.9%.As a result of the high percentage of impurities, this red copper for film

capacitor in EV with high electrical and thermal conductivity,durability and malleability is widely used in transformers,reactors,filters and mutual inductors.

2.There is no burr on the edge of copper foil strip .Surface atomization treatment makes the surface of copper strip get to a brighter and cleaner level.

In recent years, the policies of the new energy automobile industry have been frequent, and the intensive introduction of relevant policies in various places to vigorously promote the use of new energy vehicles will inevitably stimulate the demand for film capacitors. Therefore, the future application of film capacitors in the field of new energy and new energy vehicles will be the main development direction. There are generally three places in the car that use capacitors: energy storage, motor and electronic control. In the design of the power supply part of the new energy vehicle, it is necessary to use a high-voltage capacitor for smoothing and filtering applications. The internal working environment of the automobile is generally harsh, and the Laminated Copper Busbar capacitor is required to have high temperature resistance, high reliability, and long service life.

1.Strong welding, no gap with excellent appearance

2.High-quality T2 copper foil: T2 Copper is a relatively pure copper, with good conductivity and plasticity. The laminated copper busbar we produced has excellent thermal conductivity, ductility and corrosion resistance, and has good weldability.

3.Good reliability and space saving

Wire drawing 》 Stamping 》 Clearning 》 Welding 》 Plating 》 QC 》 Packaging

1 .Wire drawing:After wire drawing ,our welding components for laminated busbar present metallic appearance.Its metallic looks an advanced andsharp impression.

2.Mould preparation:We are well-experienced in mould for 25 years with morethan 20 kinds of national utility model patent.

3.Stamping:Our company has more than 30 punching machine production equipment, from 10T to 110T, which is applicable to the production of various specifications of products.The main features of these equipment are large capacity, low power consumption, stamping times per day up to 2 million times.

4.Clearning:The four-groove ultrasonic gas-phase cleaning machine is suitable for the precision workpiece with high cleanliness. Two ultrasonic grooves can be divided into fine cleaning and rough cleaning, which can achieve higher cleaning quality and continuous cleaning in large quantities.

Q1: ARE YOU A FACTORY OR A TRADING COMPANY?

A1: We are professional manufacturer of the Laminated Copper Busbar Welding Accessories for over 25 years.

Q2: CAN I GET FREE SAMPLE?

A2: Yes, We are glad to offer free samples if you are a qualified and returning customer.

For the new customer, samples fee will be deducted from the initial bulk order.

Q3: HOW LONG IS YOUR DELIVERY TIME?

A3: Our delivery time is 30 days after payment.

Q4: WHAT'S YOUR PAYMENT TERM?

A4:We accept TT, L/C and west union or you can pay through Alibaba.

Q5: DO YOU OFFER OEM SERVICE?

A5: Yes, OEM is welcome.

Q6:DO YOU HAVE AFTER-SALE SERVICE?

A6: Our quality and service is our life, so even after your buying, we still offer free after sale service.