Position:Home> Product

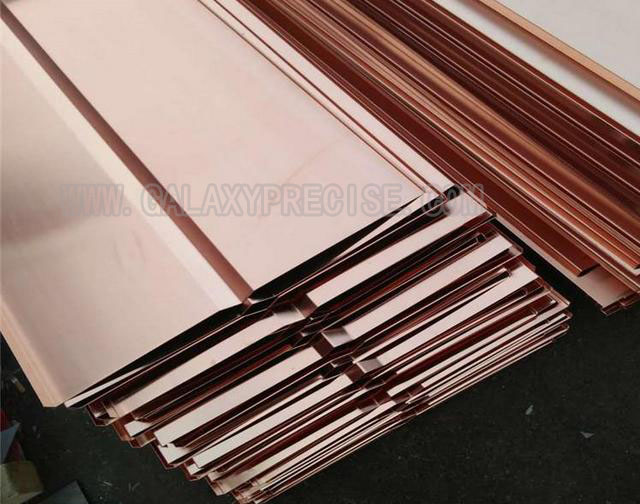

Electric Vehicle Capacitor Copper Plate

| Material | Red Copper plate |

| Features | 1. Easy installation, accurate measurement and stable operation 2.Outstanding endurable & long life-time 3.High temperature resistant |

| Specification | No standard |

Certificate | TS16949 & ISO9001 |

| Application | Busbar for Electric Vehicle Capacitor |

Product Information

The Electric Vehicle Capacitor Copper Plate is made of high-quality red copper.The copper performs excellent thermal conductivity, ductility and corrosion resistance, and has good weldability, can made by cold, thermoplastic processing all kinds of semi-finished products and finished products.

The Electric Vehicle Capacitor Copper Plate is applied in film capacitor for New energy vehicles.In general,capacitors are used in storage, motor and electric control.The composit busbar plays important part in capacitor.Soldering component of conductor material mainly use grades of C1100 cooper plate.This copper performs excellent thermal conductivity, ductility and corrosion resistance, and has good weldability.As a result,Our welding component is high temperature resistant, high reliability, long service life.laminated busbar is also called recombination busbar,a kind of multilayer composite structure busbar.It acts as a highway in distribution system.The welding component for busbar we produced is characterized by its high quality, compact-sized,easy installation,highly reliable and long service life.

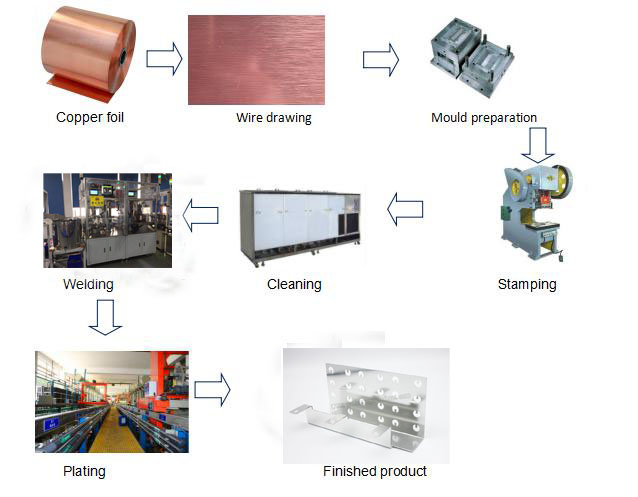

1 .Wire drawing:After wire drawing ,our welding components for composit busbar present metallic appearance.Its metallic looks an advanced andsharp impression.

2.Mould preparation:We are well-experienced in mould for 25 years with morethan 20 kinds of national utility model patent.We even served for large-scale military stamping die autowiring 10 years ago.

3.Stamping:Our company has more than 30 sets of high-speed precision punching equipments, from 10T to 110T, which is applicable to the production of various specifications of products.The main features of these equipment are large capacity, low power consumption, stamping times per day up to 2 million times.

4.Clearning:The four-groove ultrasonic gas-phase cleaning machine is suitable for the precision workpiece with high cleanliness. Two ultrasonic grooves can be divided into fine cleaning and rough cleaning, which can achieve higher cleaning quality and continuous cleaning in large quantities.

5.Welding:We are specialized in resistance welding, laser welding technology ,providing high-quality of Electric Vehicle Capacitor Copper Plate.

6.Plating:The laminated busbar can be plated with Tin, Nickel, Silver, etc.

We are specialized in precision stamping, resistance welding, laser welding, brazing TIG, argon arc and other precision welding technology .Our company introduced automatic precision silver contacts terminal welding syetem(Japan MIYACHI) .In addtion,there are glovebox welding system、automotive IC module welding system and automatic contact strip welding system.We also build precision welding joint laboratory with MADA MIYACHI.

Galaxy Tech company was established in 1993 and it has about 150 staffs.We have experienced engineering and design team, within precision electronic component manufacturing field. We dedicate to provide good cost performance composit busbar to our customers; meanwhile, we offer full range of system automatic production solutions. We always fully communicate with our customers to understand business need of every product, and help to improve the efficiency of automatic production line and maintain the competitive edge of our customers.

Our company is located in the Auto parts industry park in Xiamen City,Fujian Province,China.It covers an area of about 5,000 square meters.There are stamping division,welding division,research & development department, new energy division,purchasing department,quality department,material control department ,domestic department and international department.

☆High-tech enterprises in Xiamen City

☆Xiamen City, fast growing enterprise

☆IATF 16949 & ISO 9001 certificate

Winding with boxed traied loading

plastic wrap

Q1: ARE YOU A FACTORY OR A TRADING COMPANY?

A1: We are professional manufacturer of the Electric Vehicle Capacitor Copper Plate for over 25 years.

Q2: CAN I GET FREE SAMPLE?

A2: Yes, We are glad to offer free samples if you are a qualified and returning customer.

For the new customer, samples fee will be deducted from the initial bulk order.

Q3: HOW LONG IS YOUR DELIVERY TIME?

A3: Our delivery time is 30 days after payment.

Q4: WHAT'S YOUR PAYMENT TERM?

A4:We accept TT, L/C and west union or you can pay through Alibaba.

Q5: DO YOU OFFER OEM SERVICE?

A5: Yes, OEM is welcome.

Q6:DO YOU HAVE AFTER-SALE SERVICE?

A6: Our quality and service is our life, so even after your buying, we still offer free after sale service.